EP35 Series, ultra-compact planetary gearmotors. 12watt, 12-24volt DC micromotor.

Read moreEP65

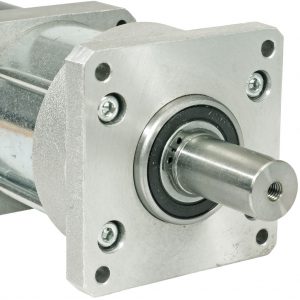

Series

Monobloc planetary gearmotors

Monobloc

Single steel tube containing both motor and the gearunit.

Quiet

Single body without any external coupling improving the noise performances.

Long life

Constant high quality is guaranteed by fully internalised production.

No maintenance required

Lubricated for life with special long-life grease.

16 to 90 watts - 12 to 170 volts d.c. permanent magnet motor.

The gearmotor type EP65 consist of a 16 to 90 watts – 12 to 170 volts d.c. permanent magnet motor, coupled with a planetary gearunit designed to drive output torque up to 30 Nm for continuous operation conditions. Both the motor and the gearunit are contained in the same steel tube allowing to obtain a single body without any external coupling between motor and gearcase, offering a better protection to the internal components from the penetration of dust, humidity or external parts, and improving the noise performances. EP65 gearunit can be supplied also coupled to mono or three phases a.c. motors up to 0.12 kW, but loosing the possibility of containing motor and gearunit into the same tube. EP65 gearmotor is supplied lifetime lubricated by means of special long life grease, and don’t require any further lubrication or servicing.

Choose your model

EP65/16W

| Reduction stagesNumber of gear sets to increase the reduction | Efficiencydifference between applied power and output power after reduction | Reduction ratioratio between input and output revolutions | Output speed (RPM)gearmotor output revolutions | Length (mm)gearmotor length | Nominal torque (Nm)power and load capacity of the gearmotor | Dynamical axial load (N)maximum load that can be applied to the gearmotor shaft | Dynamical radial load (N)maximum load that can be applied at bearing level |

|---|---|---|---|---|---|---|---|

| 1 | 0,9 | 4 | 700 | 169,5 | 0,2 | 500 | 5070 |

| 1 | 0,9 | 6 | 467 | 169,5 | 0,3 | 500 | 5070 |

| 2 | 0,81 | 16 | 175 | 183 | 0,8 | 500 | 5070 |

| 2 | 0,81 | 24 | 117 | 183 | 1,2 | 500 | 5070 |

| 2 | 0,81 | 36 | 78 | 183 | 1,7 | 500 | 5070 |

| 3 | 0,73 | 64 | 44 | 196,5 | 2,8 | 500 | 5070 |

| 3 | 0,73 | 96 | 29 | 196,5 | 4,2 | 500 | 5070 |

| 3 | 0,73 | 144 | 19 | 196,5 | 6,3 | 500 | 5070 |

| 3 | 0,73 | 216 | 13 | 196,5 | 9,4 | 500 | 5070 |

| 4 | 0,66 | 256 | 11 | 210 | 10,1 | 500 | 5070 |

| 4 | 0,66 | 384 | 7 | 210 | 15,1 | 500 | 5070 |

| 4 | 0,66 | 576 | 5 | 210 | 22,7 | 500 | 5070 |

| 4 | 0,66 | 864 | 3 | 210 | 30 | 500 | 5070 |

| 4 | 0,66 | 1296 | 2 | 210 | 30 | 500 | 5070 |

| 5 | 0,59 | 1024 | 2,7 | 223,5 | 30 | 500 | 5070 |

| 5 | 0,59 | 1536 | 1,8 | 223,5 | 30 | 500 | 5070 |

| 5 | 0,59 | 2304 | 1,2 | 223,5 | 30 | 500 | 5070 |

| 5 | 0,59 | 3456 | 0,8 | 223,5 | 30 | 500 | 5070 |

| 5 | 0,59 | 5184 | 0,5 | 223,5 | 30 | 500 | 5070 |

| 5 | 0,59 | 7776 | 0,4 | 223,5 | 30 | 500 | 5070 |

EP65/45W

| Reduction stagesNumber of gear sets to increase the reduction | Efficiencydifference between applied power and output power after reduction | Reduction ratioratio between input and output revolutions | Output speed (RPM)gearmotor output revolutions | Length (mm)gearmotor length | Nominal torque (Nm)power and load capacity of the gearmotor | Dynamical axial load (N)maximum load that can be applied to the gearmotor shaft | Dynamical radial load (N)maximum load that can be applied at bearing level |

|---|---|---|---|---|---|---|---|

| 1 | 0,9 | 4 | 700 | 199 | 0,4 | 500 | 5070 |

| 1 | 0,9 | 6 | 467 | 199 | 0,6 | 500 | 5070 |

| 2 | 0,81 | 16 | 175 | 212 | 1,6 | 500 | 5070 |

| 2 | 0,81 | 24 | 117 | 212 | 2,3 | 500 | 5070 |

| 2 | 0,81 | 36 | 78 | 212 | 3,5 | 500 | 5070 |

| 3 | 0,73 | 64 | 44 | 225 | 5,6 | 500 | 5070 |

| 3 | 0,73 | 96 | 29 | 225 | 8,4 | 500 | 5070 |

| 3 | 0,73 | 144 | 19 | 225 | 12,6 | 500 | 5070 |

| 3 | 0,73 | 216 | 13 | 225 | 18,9 | 500 | 5070 |

| 4 | 0,66 | 256 | 11 | 239 | 20,2 | 500 | 5070 |

| 4 | 0,66 | 384 | 7 | 239 | 30 | 500 | 5070 |

| 4 | 0,66 | 576 | 5 | 239 | 30 | 500 | 5070 |

| 4 | 0,66 | 864 | 3 | 239 | 30 | 500 | 5070 |

| 4 | 0,66 | 1296 | 2 | 239 | 30 | 500 | 5070 |

| 5 | 0,59 | 1024 | 2,7 | 252 | 30 | 500 | 5070 |

| 5 | 0,59 | 1536 | 1,8 | 252 | 30 | 500 | 5070 |

| 5 | 0,59 | 2304 | 1,2 | 252 | 30 | 500 | 5070 |

| 5 | 0,59 | 3456 | 0,8 | 252 | 30 | 500 | 5070 |

| 5 | 0,59 | 5184 | 0,5 | 252 | 30 | 500 | 5070 |

| 5 | 0,59 | 7776 | 0,4 | 252 | 30 | 500 | 5070 |

EP65/90W

| Reduction stagesNumber of gear sets to increase the reduction | Efficiencydifference between applied power and output power after reduction | Reduction ratioratio between input and output revolutions | Output speed (RPM)gearmotor output revolutions | Length (mm)gearmotor length | Nominal torque (Nm)power and load capacity of the gearmotor | Dynamical axial load (N)maximum load that can be applied to the gearmotor shaft | Dynamical radial load (N)maximum load that can be applied at bearing level |

|---|---|---|---|---|---|---|---|

| 1 | 0,9 | 4 | 700 | 233 | 0,9 | 500 | 5070 |

| 1 | 0,9 | 6 | 467 | 233 | 1,3 | 500 | 5070 |

| 2 | 0,81 | 16 | 175 | 245 | 3,1 | 500 | 5070 |

| 2 | 0,81 | 24 | 117 | 245 | 4,7 | 500 | 5070 |

| 2 | 0,81 | 36 | 78 | 245 | 7 | 500 | 5070 |

| 3 | 0,73 | 64 | 44 | 260 | 11,2 | 500 | 5070 |

| 3 | 0,73 | 96 | 29 | 260 | 16,8 | 500 | 5070 |

| 3 | 0,73 | 144 | 19 | 260 | 25,2 | 500 | 5070 |

| 3 | 0,73 | 216 | 13 | 260 | 30 | 500 | 5070 |

Other gearmotors that may interest you:

Series EP45 Gearmotors

EP45 Series, ultra-adaptable planetary gearmotors. 16watt, 12-24volt DC micromotor.

Read moreSeries EP70 Gearmotors

EP70 Series, extra-versatile planetary gearmotors. DC micromotor 45-120Watt, 12-170volts.

Read moreSeries EP7090 Gearmotors

EP7090 Series, extra-strong planetary gearmotors. DC micromotor 90-200Watt, 12-170volts

Read moreSeries EP45 Gearmotors

EP45 Series, ultra-adaptable planetary gearmotors. 16watt, 12-24volt DC micromotor.

Read moreSeries EP70 Gearmotors

EP70 Series, extra-versatile planetary gearmotors. DC micromotor 45-120Watt, 12-170volts.

Read moreSeries EP7090 Gearmotors

EP7090 Series, extra-strong planetary gearmotors. DC micromotor 90-200Watt, 12-170volts

Read more